PROJECTS |

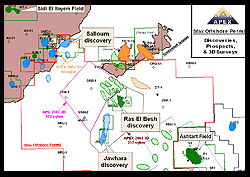

RAS EL BESH FIELD DEVELOPMENTThe Ras El Besh Field Concession is located in the central area of the Sfax Offshore Exploration Permit in the shallow waters of the Gulf of Gabes 12 km south of the Kerkennah Islands and approximately 37 km southeast of the city of Sfax. In 1995, ARCO drilled the Ras El Besh 1 (REB1), which had hydrocarbon shows in the El Garia, but was not tested. Based on the encouraging results of REB1, in 1997, ARCO drilled the Ras El Besh Well 2 (REB2), which positively tested the El Garia and encountered the 3rd thickest El Garia section on the Sfax Permit. Even so, the REB2 is located within the fault zone on the west side of the Ras El Besh horst structure and there are several faulted intervals with a total of approximately 15 m of reservoir missing. APEX estimates that there is an accumulation of approximately 89 m of El Garia nummulitic reservoir in the vicinity of the Ras El Besh structure. The REB2 well tested at an average rate in excess of 612 BOPD on a 6 hour test.

In 1995, ARCO drilled the Ras El Besh 1 (REB1), which had hydrocarbon shows in the El Garia, but was not tested. Based on the encouraging results of REB1, in 1997, ARCO drilled the Ras El Besh Well 2 (REB2), which positively tested the El Garia and encountered the 3rd thickest El Garia section on the Sfax Permit. Even so, the REB2 is located within the fault zone on the west side of the Ras El Besh horst structure and there are several faulted intervals with a total of approximately 15 m of reservoir missing. APEX estimates that there is an accumulation of approximately 89 m of El Garia nummulitic reservoir in the vicinity of the Ras El Besh structure. The REB2 well tested at an average rate in excess of 612 BOPD on a 6 hour test.

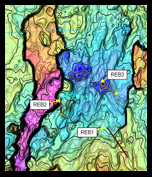

In the later part of 2004, APEX acquired a high density, high definition marine 3D Seismic Survey which was used extensively in developing APEX’s structural interpretation of the Ras El Besh Field. The acquisition of the high quality 3-D seismic program over the Ras El Besh and Jawhara prospects has allowed APEX to make very accurate interpretations of fault and structure placement as well as allowing a seismically driven determination of reservoir quality and fracture occurrence. With the aid of these high technology geophysical techniques APEX has developed the best possible interpretation of the Ras El Besh Field Concession.  APEX estimates that the Ras El Besh structure contains between 40 and 80 million barrels of recoverable oil and is finalizing plans for its development. Current plans include the drilling of two wells in the initial development phase. The well locations selected for Ras El Besh Well 3 (REB3) and 4 (REB4) are updip to both REB1&2 and within the same fault segment. It is anticipated, pending confirmation of structural interpretation, reservoir quality and commercial potential, that subsequent drilling may result in as many as four additional wells being drilled on this structural feature.

APEX estimates that the Ras El Besh structure contains between 40 and 80 million barrels of recoverable oil and is finalizing plans for its development. Current plans include the drilling of two wells in the initial development phase. The well locations selected for Ras El Besh Well 3 (REB3) and 4 (REB4) are updip to both REB1&2 and within the same fault segment. It is anticipated, pending confirmation of structural interpretation, reservoir quality and commercial potential, that subsequent drilling may result in as many as four additional wells being drilled on this structural feature.

The Plan of Development for Ras El Besh Field is predicated on the use of a drilling jack-up that departs at the end of the initial drilling program. The well(s) are drilled through a pre-installed template that has slots for the drilling of up to six wells and which is fitted with docking piles for the future installation of the MOPU as shown.

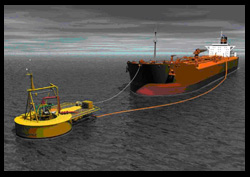

Phase One – DrillingA simple, low-cost, Wellhead Support Structure will be utilized to span the distance between the template and the hull of the jack-up drilling rig and provide support for the well conductors during drilling, and also for subsequent oil production operations. It is designed such that, at the appropriate time, the structure can then be connected to the production jack-up (MOPU).Phase Two – ProductionInitial drilling operations from the well template will be centrally located within the large Ras El Besh geologic feature. This will facilitate the directional drilling of multiple development wells as necessary to adequately develop the field.Water depths in the area where the production facilities will be located, and from which drilling operations will be conducted, are between 12 and 15 meters, which is insufficient for a mooring station, an FSO or the loading of a sales tanker. Consequently, it is anticipated that the FSO will be anchored approximately 1-1/2 km southeast of the location of the jack-up facility (MOPU) where water depths exceed 20 meters. Crude oil will be transferred to the FSO utilizing pumps located aboard the jack-up production facility, through a sub-sea pipeline, to the tanker mooring facility. At the mooring facility the oil will flow up through a sub-sea riser to a CALM (catenary anchor leg mooring) buoy which will be utilized to secure the FSO. CALM systems are named for the characteristic curve of the anchor legs that hold the buoy in position. These buoys are also often referred to as a single buoy mooring (SBM), mono-buoy or loading buoy. CALM buoys can be designed to berth any size tanker up to and including Ultra Large Crude Carriers (ULCCs). The primary applications for CALM systems are: (1) short term mooring for import and export of fluids between onshore or offshore facilities and a tanker; (2) permanent mooring for production and storage systems; and, (3) semi-permanent mooring with an easy disconnect capability to evacuate the facility in case of severe weather conditions. The loading of the FSO will occur through a Coflexip hose.  An artist’s rendition of the mooring facility (CALM) and FSO to be used for the development of the Ras El Besh Field is shown at right.

An artist’s rendition of the mooring facility (CALM) and FSO to be used for the development of the Ras El Besh Field is shown at right.

Oil production will be accumulated in the FSO until approximately 180-210,000 bbls of crude oil is in storage. Once such a volume has been reached, tankers of opportunity bound for various refineries in the northern Mediterranean will be used for offtake and marketing. Prices typically received for the quality of crude oil to be produced from the Ras El Besh Field are $2-3 under the Brent benchmark. |